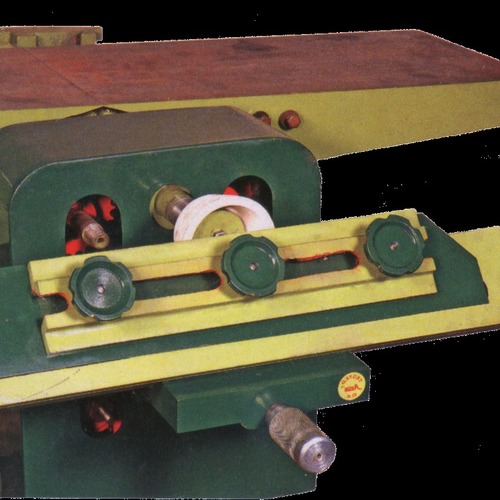

GRINDING ATTACHMENT ( COMBINE)

Product Details:

- Product Type Woodworking Equipment

- Machine Style Horizontal

- Power Electric

- Color Green

- Warranty 6 MONTH

- Click to view more

GRINDING ATTACHMENT ( COMBINE) Price And Quantity

- 8000.00 - 10000.00 INR/Piece

- 1 Unit

GRINDING ATTACHMENT ( COMBINE) Product Specifications

- Woodworking Equipment

- 6 MONTH

- Green

- Horizontal

- Electric

GRINDING ATTACHMENT ( COMBINE) Trade Information

- 1 Week

- Yes

- Within a certain price range free samples are available

- All India

Product Description

A grinding attachment is a device that is added to another machine, typically to add grinding capabilities to it. These attachments are commonly used in various industries for tasks such as sharpening, grinding, polishing, and shaping workpieces. Here's an overview of grinding attachments and their applications:

-

Lathe Grinding Attachment: This type of attachment is added to a lathe machine, allowing it to perform internal and external cylindrical grinding operations. It's particularly useful for creating smooth and precise cylindrical shapes on workpieces.

-

Tool and Cutter Grinding Attachment: Tool and cutter grinders are used to sharpen and regrind cutting tools like drills, milling cutters, and end mills. A tool and cutter grinding attachment is added to a tool and cutter grinder machine to provide the necessary grinding capabilities.

-

Surface Grinding Attachment: Surface grinding attachments are added to milling machines, allowing them to perform surface grinding operations. This is used to create a flat surface finish on workpieces, and it's commonly used in metalworking.

-

Belt Sander Attachment: Some machines can be fitted with belt sander attachments, which are used for sanding and finishing tasks. These attachments often have a flat sanding surface and a continuous abrasive belt for smoothing and shaping workpieces.

-

Angle Grinder Attachment: Angle grinders are versatile handheld tools used for cutting, grinding, and polishing. Attachments like wire wheels, abrasive discs, and flap discs can be added to angle grinders to extend their functionality.

-

Polishing Attachment: Polishing attachments are used for buffing and polishing surfaces to achieve a smooth and glossy finish. They can be added to various machines, such as bench grinders, to convert them into polishing tools.

-

Die Grinder Attachment: Die grinders are small, high-speed rotary tools used for grinding and shaping. Various attachments, including grinding stones, burrs, and sanding drums, can be added to die grinders to expand their capabilities.

-

Bench Grinder Attachment: Bench grinders can be enhanced with different grinding wheels and wire brush attachments for tasks like sharpening tools and removing rust and paint.

-

Universal Grinding Attachment: Some versatile grinding attachments are designed to be adaptable to different machines, allowing them to perform a range of grinding operations on various materials.

Grinding attachments are valuable tools that add versatility to existing machines, enabling them to perform grinding and abrasive operations, which are crucial in many industrial and workshop applications. The specific type of grinding attachment you choose will depend on the machine you have and the specific grinding tasks you need to accomplish. Proper safety precautions and operating guidelines should be followed when using these attachments to ensure safe and efficient grinding operations.

Is this conversation helpful so far?

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese